Recognize these issues?

Different employees read and understand GD&T differently. There is no standard approach.

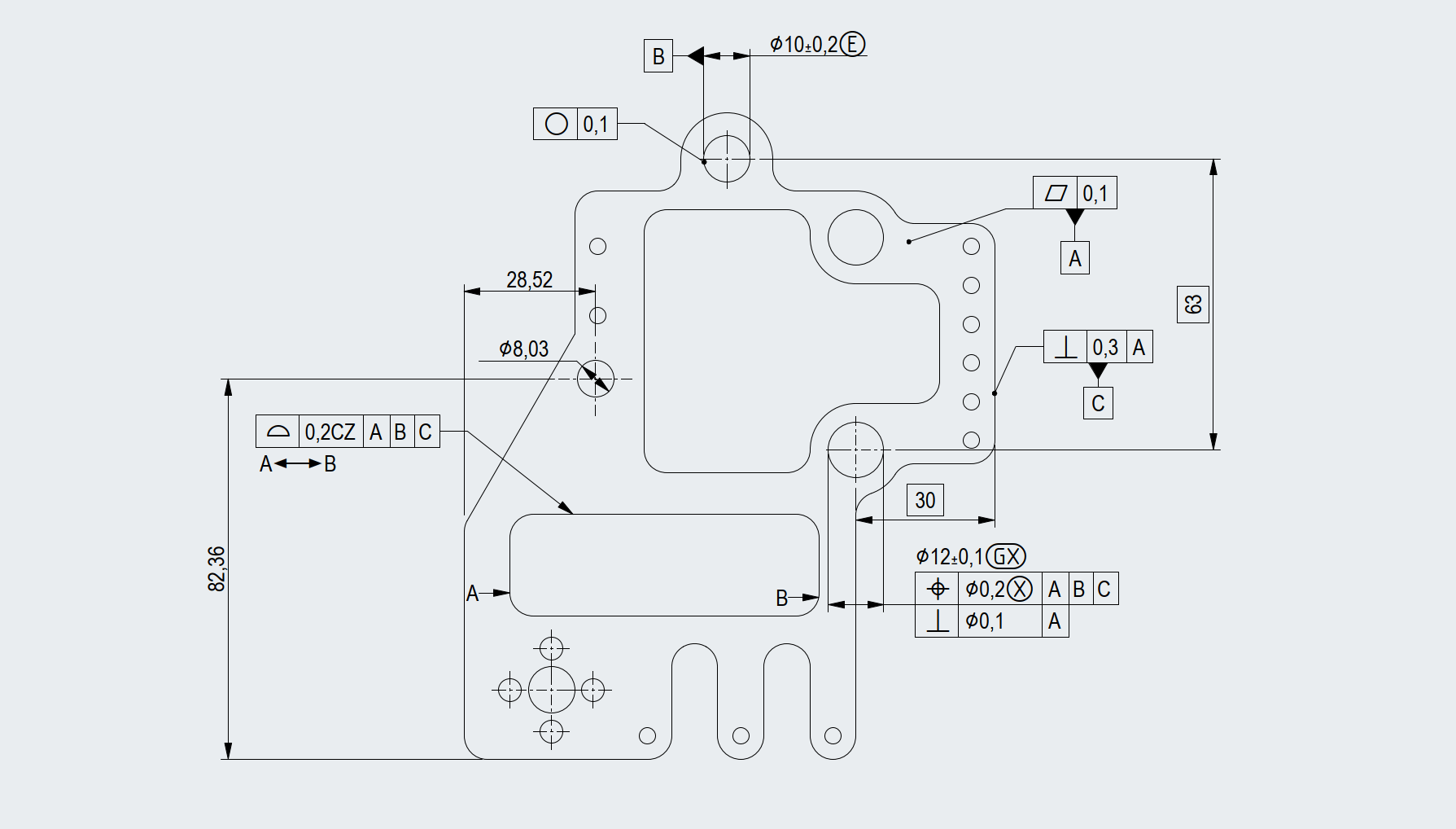

How can I better and unambiguously safeguard the functionality of my workpiece?

How can we help

First, we estimate the level of each participant. From there we arrive at a standard approach using practical exercises.

Course objectives

The main goal of the course is to get everyone into alignment regarding the application and interpretation of GD&T. There is time and space for discussion during the course. This sharpens communication and ensures that everyone is on the same page.

At the end of the two-day course, participants will be able to:

- correctly interpret any given GD&T.

- functionally apply GD&T tolerances independently, when formulating product specifications and producing drawings.

Target group

This course is suitable for a wide range of team members, including CAD engineers, work planners, quality control engineers and anyone else whose work requires a familiarity and understanding of GD&T.

Course content

Introduction

- GD&T and 2-point size dimensions, a comparison

- ISO GPS Terms and definitions, Envelope principle and basic rules

- ISO 14405 Linear size modifiers and non-size dimensions

- ISO 22081-2021 General geometric specification

Datums

- According to standard ISO 5459-2011

- Degrees of freedom

- Datums, Datum systems and sequences

- Datum targets

GD&T symbols

- According to standard ISO 1101-2017 - ISO 5458-2018 - ISO 2692-2021

- Flatness, straightness, circularity and cylindricity

- Perpendicularity, angularity and parallelism

- Tolerance of position, coaxiality, concentricity and symmetry

- Multi segment tolerancing and patterns

- Profile of a surface and profile of a line

- Circular runout and Total runout

- Maximum material principle, projected tolerance zone and Functional gages

- Direction feature, Intersection plane, Orientation plane and Collection plane

- Contacting feature, Variable distance for common datums

Theoretical and practical exercises represented in Model-Based Definition PMI 3D models

Course duration

The full course takes two days, which need not be consecutive. Our training hours are flexible.

What our clients are saying

Frequently Asked Questions

Get answers to common questions quickly and learn more about our services and training solutions.

Standards have expanded considerably in recent years. This has made it impossible to cover every standard in detail within a two-day course.

We are always willing to set up an intake exercise to gauge the current level of knowledge within your company. This helps us create a learning path that is tailored to individual needs.

Yes, we are always willing to work to specific customer needs. We are flexible and can respond quickly to meet customer requirements.

We will review your question thoroughly and let you know what is feasible for us to address or how our knowledge network can assist you.

Differences can be addressed during the course, where requested.

Basic training is also available according to the ASME standard.

Yes. If this involves too much work, we will supply a quote for a solution.