Recognize these issues?

Which dimensions are functional now? Which tolerances will affect the function of my design? Are all my components adequately dimensioned?

How we can help

By focusing on the tolerance vector diagram and its possible influences, you will gain a better understanding of the tolerance sensitivity of the design.

Course objectives

The purpose of this training is to encourage draftspeople and product developers to consider tolerances and their impact on their product.

At the end of the two-day course, participants will be able to:

- understand the dimensional and functional relationships of systems and components.

- control and structurally resolve tolerance risks.

- translate GD&T to the tolerance studies.

- apply basic statistics to tolerance studies.

- make assumptions in a design, draw a conclusion based on the result and optimize.

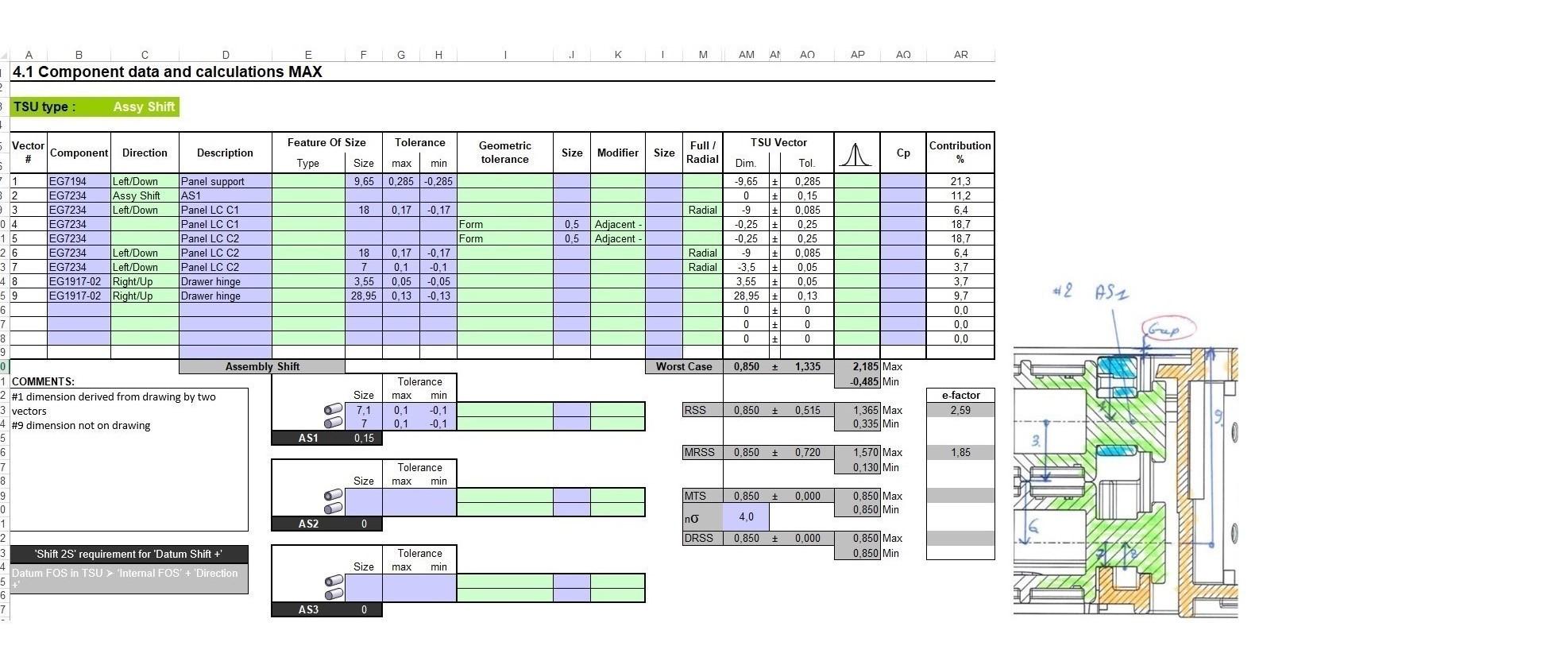

The tool used is an Excel spreadsheet with a 1D vector diagram as a basis.

Target group

The course is intended for anyone whose work involves product development and has preferably already taken the GD&T short course.

Course content

Introduction

- importance of tolerance analysis, understanding tolerances

- basic principles GD&T

- understanding tolerance zones and reference systems

Tolerance diagram

- setting up 1D vector diagram on workpiece and assembly

- GD&T in a stack-up

- assumptions in a tolerance analysis

Statistics

- basic statistics

- statistics in tolerance analysis

Points of attention in stack-ups

Trigonometry, assembly shift

Practical exercises.

Course duration

The full course takes two days, which need not be consecutive. Our training hours are flexible.

What our clients are saying

Frequently Asked Questions

Get answers to common questions quickly and learn more about our services and training solutions.

The spreadsheet works only with symmetric distributions. Asymmetric distributions are reduced to symmetric ones. For this reason, it is not possible to go down to the µ's accurately.

In a fairly simple way, you can quickly gain insight into your tolerance structure, repeatability, and the sensitivities of your design.

Yes, we are always willing to work to specific customer needs. We are flexible and can respond quickly to meet customer requirements.

Yes. If this involves too much work, we will supply a quote for a solution.