Recognize these issues?

What does this dimension actually mean? Team members are interpreting dimensions on drawings differently.

We have difficulty reading 2D drawings correctly and unambiguously across the organization.

How we can help

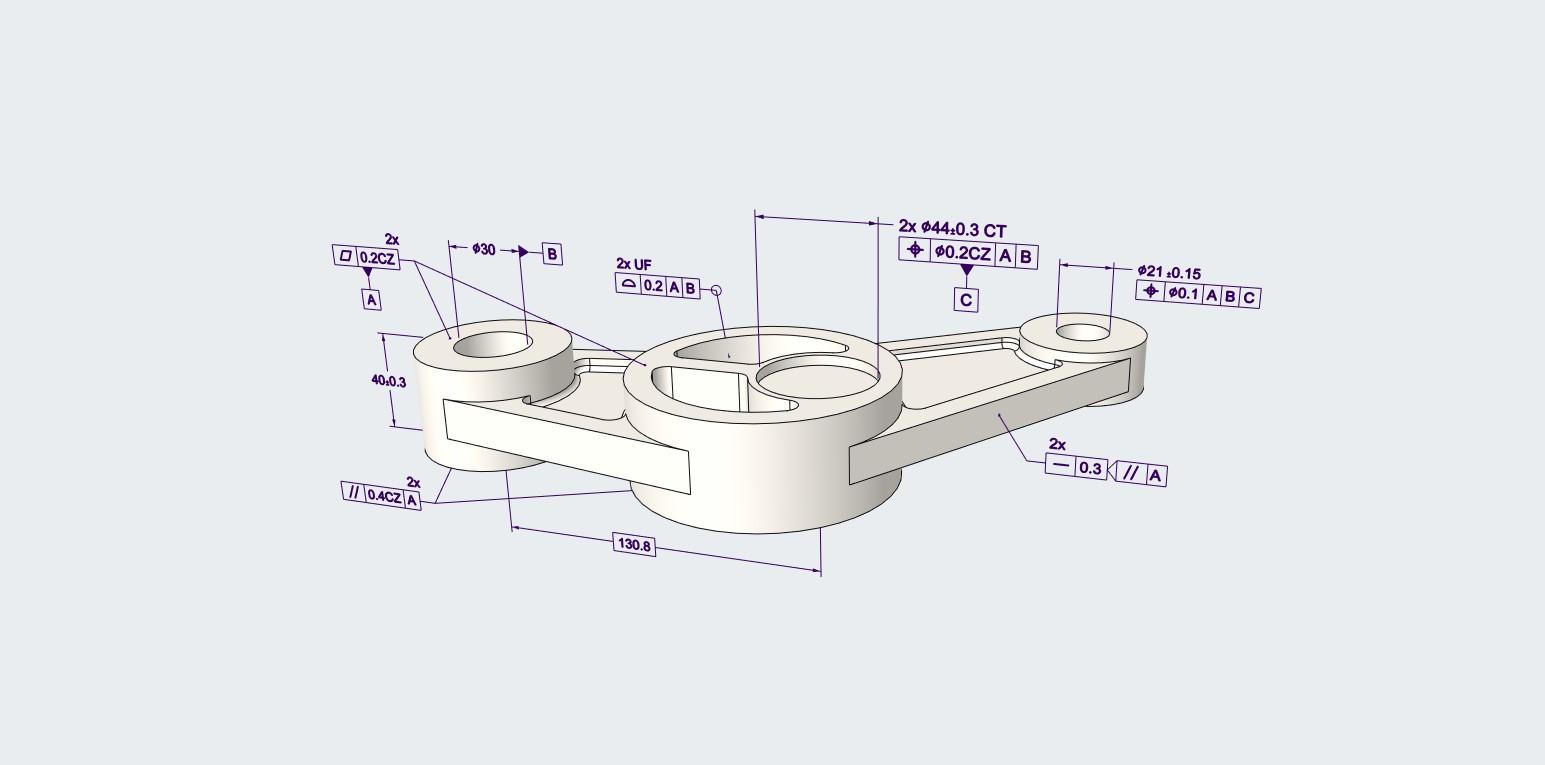

We visualize the structures of dimensioning a 3D model. This approach has numerous benefits for a variety of business processes.

Course objectives

The goal of the course is to become familiar with the Model-Based Definition (MBD) process. It also covers the annotation mode – the tools for annotating a 3D CAD in PTC Creo, optionally with the Creo GDT-Advisor module.

You will learn to transfer 2D information into a 3D model so that all Product Manufacturing Information (PMI) is present so that the 3D model becomes machine readable. Ultimately, one no longer speaks of a 2D drawing, but a Technical Data Package or a Product Definition Data set.

At the end of the course, participants will be able to:

- have a better understanding of the MBD process and of how MBD models are created and PMI is required.

- be able to use a 3D CAD model as a tool to communicate better and more unambiguously across the organization.

This training can be expanded with topics from the GD&T course.

Target group

The course is primarily aimed at designers who create and approve 3D models.

Course content

Introduction to Model-Based Definition

Digital product definition data practices

ISO 16792:2021

Classification codes for drawings and data sets

General model requirements

Preparing Models for Annotation

Creating Annotation Elements

Modifying Annotation Elements

Setting up Combination States

Teaching a best-practice workflow

Theoretical exercises

Practical exercises on client 3D models

Creo GDT Advisor is optional

Course duration

The full course takes one to two days, depending on the selected options. Our training hours are flexible.

What our clients are saying

Frequently Asked Questions

Get answers to common questions quickly and learn more about our services and training solutions.

No, it is only for the Creo Parametric CAD system. The GD&T Advisor extension can also be included in the training.

Post-hoc process options will be addressed during training. Contact your reseller for more information on specific options and how you can use them to improve your business.

Yes, we are always willing to work to specific customer needs. We are flexible and can respond quickly to meet customer requirements.

Yes. If this involves too much work, we will supply a quote for a solution.